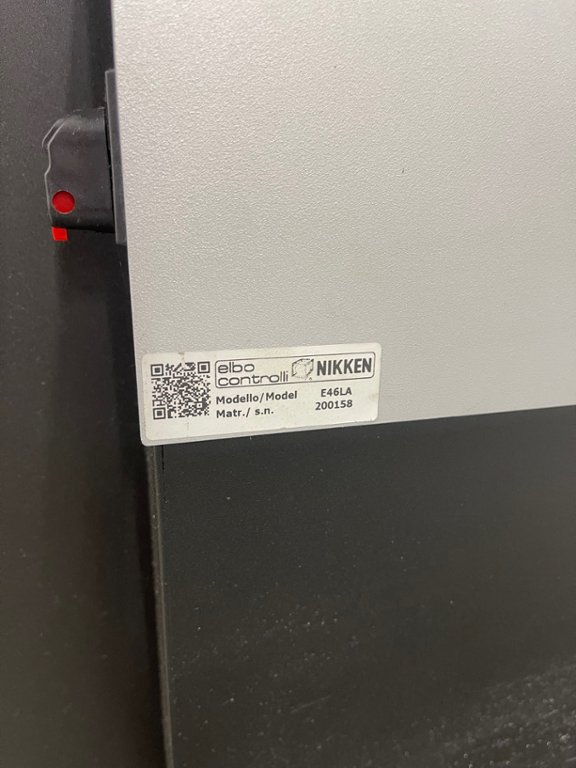

Lot 3 - *NOW SOLD* Nikken Elbo-Control L1 E46LA Advanced Tool Presetter

Description:

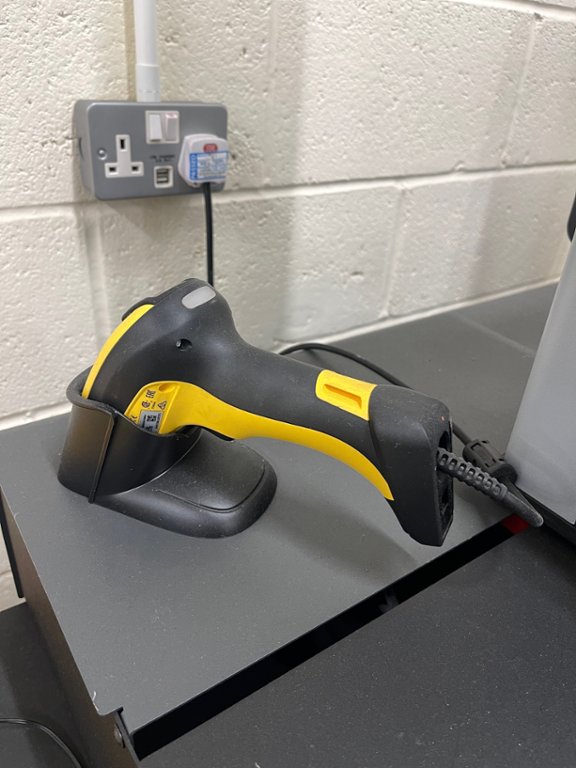

* If purchased with the Matsuura it is not only a tool pre-setter but a complete tool ID system where you scan the QR tool on the Nikken Elbo and then the laser stores the tool offsets in its memory, when you walk over to the Matsuura and scan it into the machine it automatically updates the tool offset in the control.

Measuring range: Diameter max 400 mm (radius 200 mm); height max 600 mm.

Motor providing automatic rotation of the spindle with pneumatic engagement of the motion transmission providing zero backlash (patented system).

C Axis display for both spindle body and spindle-holder.

Standard mechanical/electronic and optical equipment:

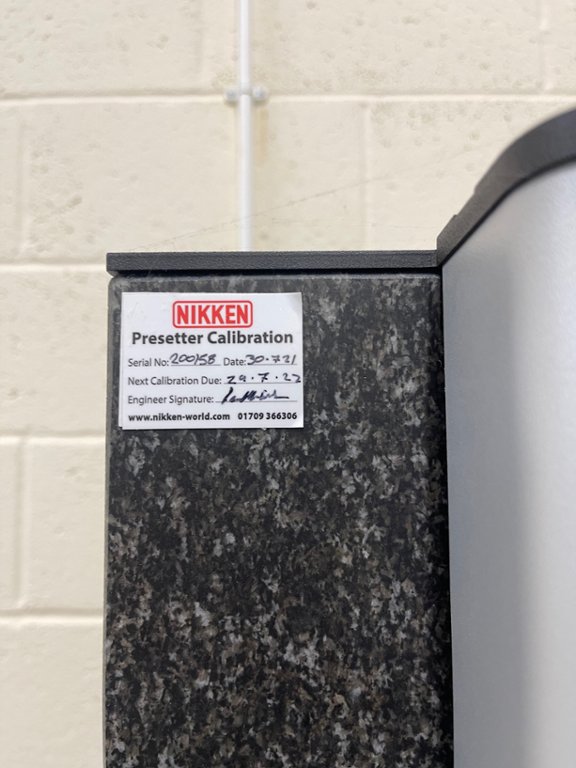

Base and column made of natural granite to guarantee the maximum accuracy: linearity max error 2 μm/Mt – certification with Taylor Hobson res.1 μm/Mt. electronic millesimal level.

ELBO CONTROLLI NIKKEN Linear Transducers in optical glass type AS 371 certified HP laser: Axes resolution: X= 1 μm, Z= 1 μm.

Machine structure in stainless steel offering high mechanical strength and long life, floor mounted with 3 fixed supports and one adjustable support in steel.

ISO / BT / HSK / VDi... etc. Interchangeable rotating spindle-holder (to be specified) max run-out error < 2 μm.

Spindle Index in four angular positions: 0°-90°-180°-270°.

Spindle-holder Identification System (SP-ID) with NFC technology to automatically identify the spindle-holder after each replacement.

Linear slideways: 2 for X axis slideways and 1 for Z axis slideway.

Double re-circulating ball bearing slides (four in total), lubricated for life. Universal electro-mechanical tool clamping (ISO only).

Pneumatic-mechanical braking of the spindle-holder rotation with radial compensation of the clamping force – no axis angular run error.

Constant load Archimedean spiral spring (as opposed to a mass counter-balance system).

Vision-system for tool measuring and cutting inspection consisting of:

C-MOS sensor – Framed image area 10 x 10 mm.

Magnification around 26X.

Bi-telecentric lens.

Optical doublets at low F/Number in order to eliminate the error of the clearness circle.

Red light episcopic LED’s illuminator with ring lens, red light diascopic LED puntiform illuminator.

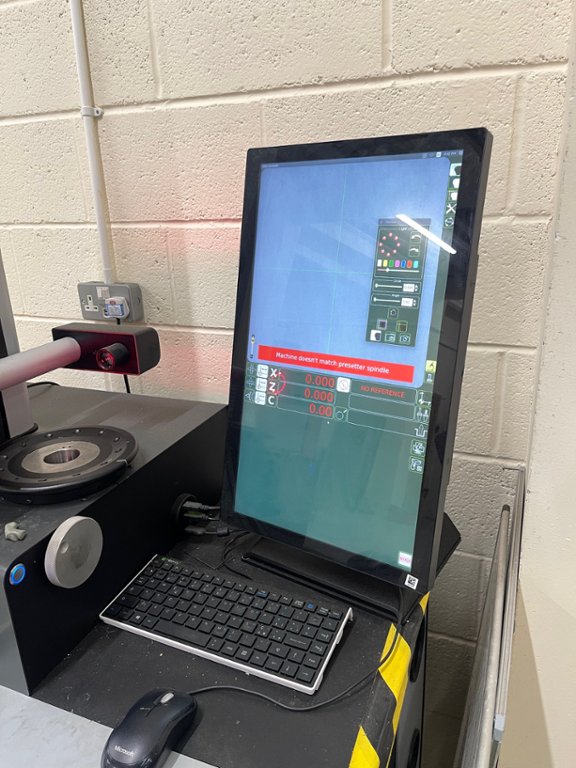

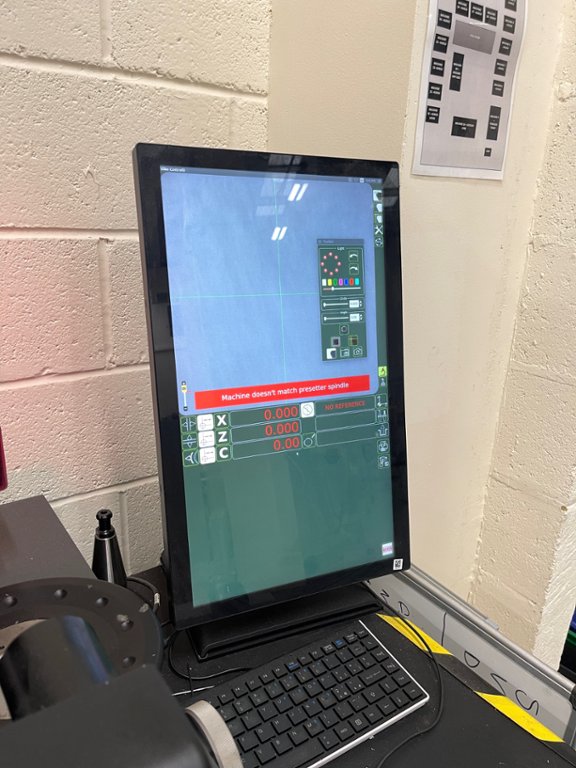

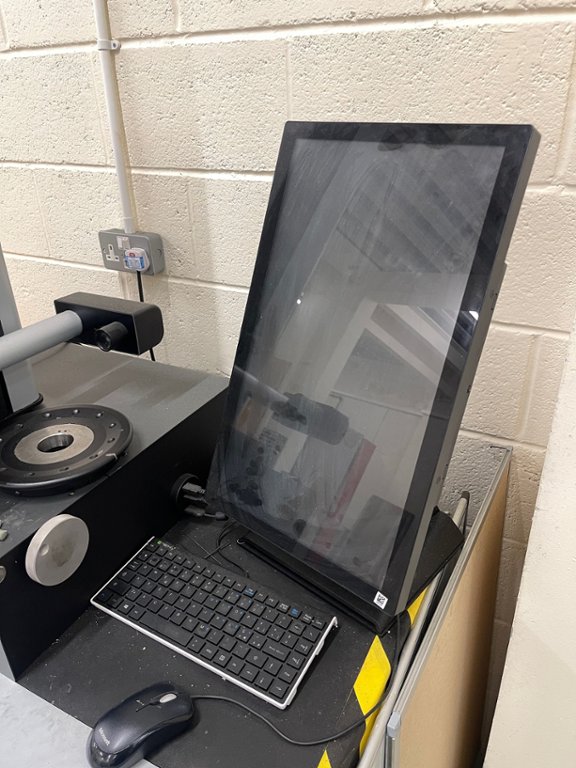

Machine operator interface through:

Full HD LCD 22” colour Touch Screen monitor.

Intel I3 Quad Core Processor.

UBUNTU LINUX 14.04 LTS operating system.

Data storage on solid state disk SSD.

X and Z axes lock management for a translation speed lower than 2 mm/sec.

Four USB ports.

Theoretical measurement and tolerance management.

Tool set and Post Processor universal generator.

Automatic change of CNC machine origin allocation.

Printable tool set report.

Spindle holder auto rotation with automatic tool measurement cycles for single cutter or multi-edged cutters. DXF format drawings import capability for overlaying a drawing on a live tool profile.

Tool profile acquisition exportable in DXF format.

Ready for TiD infrastructure for tool identification and data transfer using a data matrix tag/code.

Overall dimensions: Length = 1282 mm, Height = 1874 mm, Depth = 672 mm. Net weight: 270 Kg.

E46LA

X Axis Measure (Diameter) 400

Z Axis Measure (Length) 600

Natural Granite Base & Column ✓

Interchangeable Spindle Cartridge ✓

C Axis Display Spindle Body and Spindle Cartridge ✓

Interchangeable Spindle Max. Run-Out Error 2µm

Automatic Rotation of the Spindle ✓

Spindle Index in four Angular Positions (0º, -90º, -180º, -270º) ✓

Spindle Rotation Brake Pneumatics

Spindle Identification System (NFC recognition) ✓

Clamping System Manual Mechanics

Tool Inspection Function/Capability ✓

Elbo Controlli NIKKEN Triple Camera System (Cutting Edge Inspection) ✗

Main Camera System Resolution 1µm

Main Camera System Measuring Range (C-MOS Sensor Framed Image Area) 10mm x 10mm

Secondary 'Twin' Camera System Measuring Ranges (Framed Image Area) ✗

Main Camera Magnification 26X

Secondary 'Twin' Camera System Magnifications ✗

Elbo Controlli NIKKEN Certified Optical Scale Axes Resolution 1µm

Elbo Controlli NIKKEN GS371 Certified 'Natural Granite' Optical Scale Axes Resolution ✗

Touch Screen System (Operator Interface) TFT 22" HD Colour Touch Screen

Keyboard and Mouse ✓

Electronics/Processor Intel i3 Quad Core Processor

Firmware/Operating System Ubuntu Linux LTS

Data Storage SSD

Elbo Controlli NIKKEN Tool Management Software E46L software

Tool Set Management and Post Processor Universal Generation ✓

DXF File Import and Creation ✓

Balluff Read/Write Ready (Balluff Hardware Required)? ✓

Elbo Controlli NIKKEN TiD Ready? ✓

Elbo Controlli NIKKEN TP32 Ready? ✓

Elbo Controlli NIKKEN IS 'Integrated Solution' with Twin Screen and Dual OS Option Ready? ✓

Export Information

Please note: If you are successful in purchasing an item and wish to export it from the UK, a charge of £75.00 will be automatically added to your invoice to cover preparation of the goods and completion of the required UK export customs declarations. This process has been a mandatory UK export requirement since 1 January 2021.

All invoices are issued on an Incoterms FCA basis.

Exports outside the EU may require an export licence. Where applicable, a further charge of £250.00 will be automatically added to your invoice. Please also note that, while an export licence is being processed, the purchaser is responsible for placing into storage until the licence is issued.

* Please note all dimensions stated are approximate, however the accuracy cannot be guaranteed and should be verified by the bidder before bidding.

Bid information

Time remaining

20 Apr 2023 15:00:00 BST